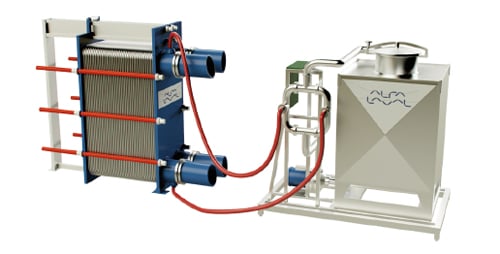

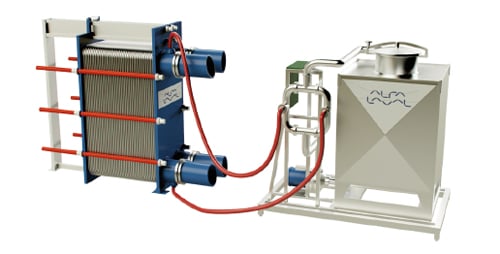

Cleaning In Place (CIP) equipment

(Information in English only - Tiedot vain englanninkielisenä)

When fouling occurs in your heat exchangers, a CIP system enables quick, cost-effective and easy in-line cleaning without dismantling the equipment. By eliminating the repeated and unnecessary opening of your equipment, you drastically reduce both spare parts consumption and the number of man-hours required for cleaning.

CIP units are very easy to operate:

- Connect the CIP unit to the heat exchanger

- Mix the cleaning agent with water in the tank and heat it up

- Circulate the cleaning solution for a few hours

- Drain and rinse

- Disconnect the CIP unit

- The heat exchanger is back to full performance capacity

CIP 200L and 400L technical brochure - easy to handle, mobile units

CIP 1800L and CIP 2800L technical brochure - skid-mounted units ideal for medium to large heat exchangers

Backflush equipment

Although plate heat exchangers have long been associated with energy conservation using natural resources such as lake water, river water, sea water and water from cooling towers, with these natural resources come natural debris such as sand, mussels, leaves and seaweed. To help the plate heat exchanger operate efficiently, an Automatic Backflush Valve can be used.

What is backflushing?

Backflushing is the reversal of flow for a short period of time. It flushes out matter that has

accumulated at the plate heat exchanger inlet. A typical setting is three times a day for thirty

seconds. By automatically removing this loose debris on a daily basis, the backflush valve will

contribute to many years of trouble-free service.

Automatic backflush valve technical brochure

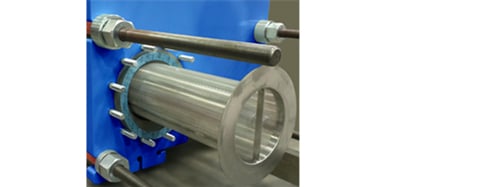

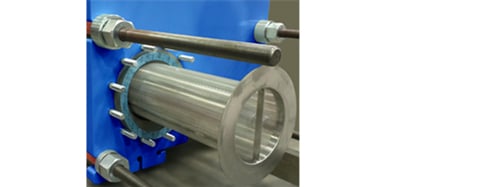

Plate heat exchanger port filtration

Port filters prevents foreign objects from entering and clogging of the heat exchanger. The filter is designed to operate in conditions involving sea water, process water, cooling tower water or any kind of water containing particles with potential risk of disrupting the performance of the system.

PHE port filtration technical brochure

Service tools

Specially developed service tools protect gasketed plate heat exchangers from faulty service and maximize their performance.

Example service tools:

- Tightening devices – used for opening and closing

- Ratchet spanners – used for opening and closing

- Thread cleaner and nut transporter – used for opening/closing and cleaning tightening bolts

- Lifting devices for large heat exchangers – used for handling of bolts and plates during assembly and disassembly

Are special tools really necessary?

- Yes, correct service tools are necessary to perform the service properly

- Without these tools, damage to the equipment might be greater than the savings made on the tools