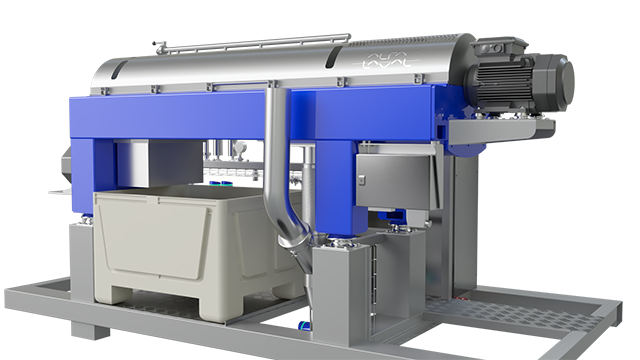

Foodec Oil Plus

Alfa Laval Foodec Oil Plus decanters are engineered for the high-efficiency extraction of all free oil and fat from animal wet rendering processes. By maximizing the recovery of meat fat and enhancing fish oil processing, they help ensure the best possible utilization of raw materials. Easy to operate and maintain, this latest Alfa Laval decanter centrifuge innovation delivers a short payback time and a low total cost of ownership.

Experience the highest possible yield and clean discharge

- Long retention time, maximizing oil extraction and uptime

- Validated and proven technology, reaching up to 99.5 Vol.% oil/fat purity, requiring little further processing

- Simplified process setup reduces the need for peripheral decanter oil equipment such as pumps, tanks, piping, etc.

- Low total cost thanks to reduced energy consumption and maintenance costs, often resulting in a pay-off time of less than one year

- Stable operation with open outlets maintains a stable interphase even with fluctuations in feed flow or composition

- Available as a standalone component or a plug-and-play skid, needing minimal change in your existing process

Recover virtually all the free oil available in the feed

Building on more than half a century of experience in developing decanters for oil production, Alfa Laval has developed the Foodec Oil Plus range of decanter centrifuges, designed to extract nearly every drop of free oil and fat.

The centrifuge achieves purities as high as 99.5%, leaving behind only tiny traces of water or fine solids, while delivering the highest defatting effect on solids. In high-demand applications—such as the wet rendering of cattle, pork, poultry and insects, or fish oil processing from whole fish, by-products and crustaceans—the technology enables a higher protein content in the final meal.

Easy flushing and CIP procedures allow all wetted parts to be effectively cleaned.

The features that make the difference

Everything you need to meet your challenges today – and tomorrow

Alfa Laval continuously improves its decanter solutions to help customers convert by-products into valuable materials, achieving greater yield with less water, energy and waste, leading to higher profitability. The state-of-the-art Alfa Laval decanter centrifuge handles varying flow conditions and high levels of solids in the feed as well as fluctuations in oil content, all without the need for operator intervention.

SolidsProtect

Flow-optimized solids outlet with wear protection

The innovative 360° outlet design ensures an even discharge of solids and minimal resistance. The outlet can handle high flow rates without blockages. SolidsProtect outlets feature replaceable wear saddles that maximize reliability and uptime of your decanter centrifuge.

FeedProtect

Feed zone with replaceable wear protection

The uniquely designed FeedProtect feed zone ensures gentle product acceleration and minimal turbulence, resulting in low abrasion and power consumption. The FeedProtect design is equipped with replaceable wear-protection liners, ensuring high uptime of your decanter centrifuge.

FlightGuard

Robust wear protection for conveyor flights

FlightGuard wear protection consists of tiles welded to the conveyor, providing robust wear resistance and prolonged uptime in highly abrasive applications.

EasyLift

Spring loaded cover, that simplifies servicing

The patented spring-loaded hinged design makes it easy to open even the heaviest cover by hand. This also helps ensure quick, safe access for maintenance and service of your decanter centrifuge.

OilPlus

Maximized oil extraction

Special solids and fluid interaction to gain maximized oil recovery.

How does Foodec Oil Plus work?

This Alfa Laval decanter centrifuge is intended for a three-phase suspension, where one discharge phase is for oil only. The working principle is similar to a skimmer. The incoming feed is effectively separated into oil and wet slurry.

The product is fed into the bowl through an inlet tube and is accelerated by the inlet rotor. Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor that is purpose-built for efficient oil recovery. Centrifugal force separates the oil from the feed slurry, making the (lower density) oil accumulates at the liquid surface, while the solids are kept in suspension and are discharged, as a slurry, in the conical end together with the water. Oil extraction takes place along the entire length of the cylindrical part of the bowl.

Fish oil processing

In the rendering method of oil extraction, adding a Foodec Oil Plus decanter can increase the oil extraction rate by up to 3%, while also reducing fat in dry matter (FiDM) by at least 2%—with even greater fat reduction observed in the final fish meal.

This not only increases the revenue from the oil fraction, but also raises the market value of the protein due to the lower fat content. As an added benefit, the extracted oil is so clear that further processing in a high-speed separator can be kept to a minimum.

Optimize your production with Alfa Laval Services

Investing in an Alfa Laval decanter centrifuge gives you access to a Service Agreement that helps boost reliability and maximize uptime when dealing with feed stocks containing particles that cause wear on the bowl and conveyor. We provide service kits that make it easy to carry out service tasks, with skilled Field Service Engineers supporting your exact needs.

Automation

Decanter centrifuges equipped with variable frequency drives (VFD) are available with control solutions to meet specific operating requirements, from basic decanter operations to advanced functionality. Alfa Laval decanter automation can also help you achieve specific process performance goals, along with easy, automated process adjustments, real-time status feedback and automated cleaning cycles.

Connected Services

Decanter centrifuges equipped with automation can be fitted with IoT hardware to streamline data-driven decisions that ensure more uptime and lower cost of ownership. You can then quickly and easily access key Alfa Laval expertise, along with condition monitoring and process optimization.

Asiakirjat

Let us help you

It is easy to integrate these decanter centrifuges into existing or new wet rendering processing lines to improve oil yield and ensure a deoiled meal. Our industry experts can analyze your specific situation and optimize your processes to help you achieve your business goals and sustainability targets.