Niagara Wet Surface Air Coolers

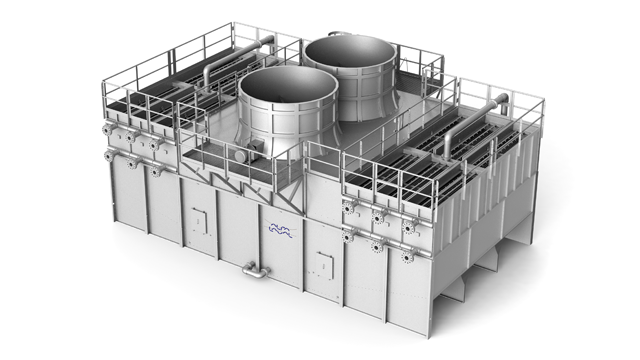

The Niagara range of Wet Surface Air Coolers are efficient and durable closed-loop, evaporative coolers and condensers, used in liquid cooling, single phase gas cooling and turbine exhaust vacuum steam condensing applications. Each WSAC cooler or condenser is custom-designed to fit the specific application, and are tailored to meet the unique needs of the most demanding applications.

Proven philosophy for lower temperatures

Alfa Laval Niagara Wet Surface Air Coolers (WSAC®) are efficient closed-loop, evaporative cooling systems designed for the power, process, wastewater, natural gas and petrochemical industries. These fluid cooling and vapor condensing systems are optimized for industrial applications where rugged designs, and cost-effective, efficient closed-loop cooling and condensing duties are required.

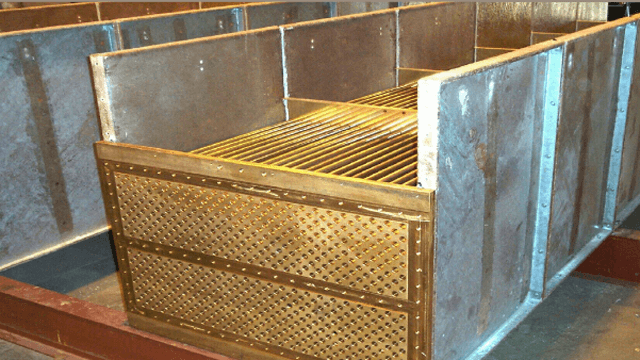

The Alfa Laval Niagara WSAC system is one of the most efficient and durable evaporative coolers available – capable of cooling process fluid to within 5°F of the surrounding wet bulb temperature. Our wet surface air coolers are constructed with heavy gauge steel double brake flanged on all four sides, and welded in all corners – providing extreme rigidity, extending service life and increasing overall durability to customers worldwide. Our WSAC system offers improved efficiencies over traditional heat exchangers used throughout the industries.

Toiminto

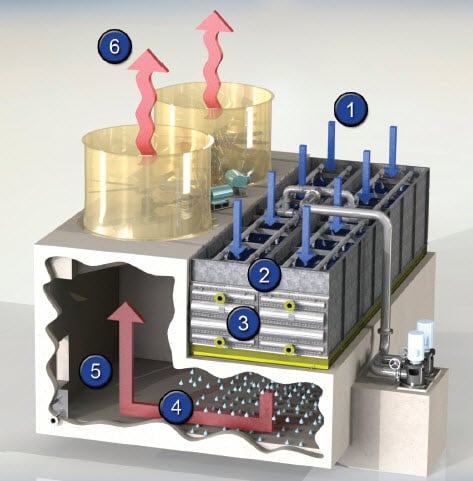

In a WSAC® system, warm process fluids or vapors are cooled in a closed-loop tube bundle (the process fluid being cooled never comes in contact with the outside air). Open loop water is sprayed and air is induced over the tube bundle resulting in the cooling effect.

- Air is induced downward over the tube bundles.

- Water is sprayed over the bundles, and travels downward along with the air.

- A warm process stream (liquids, vapors, or hydrocarbons) flows through tube bundle. Heat from the process stream is released to the cascading water, and a cooled process stream exits.

- Vaporization transfers heat from cascading water to the air stream.

- The air stream is forced to turn 180° providing maximum free water removal

- Fans discharge air vertically at a high velocity to minimize recirculation