Moduulit

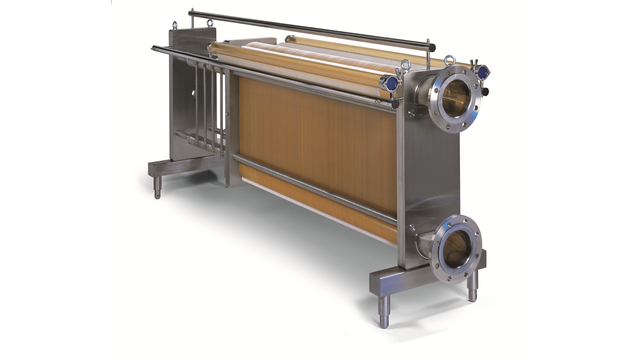

The open-channel design of the unique plate-and-frame modules from Alfa Laval makes the units suitable for practically any viscosity, and even for suspended solids. The Alfa Laval plate-and-frame modules are approved for sanitary operation and offer great advantages when product purity is paramount and perfect cleaning and disinfection is a must

Plate-and-frame modules to fit every need

Basic membrane filtration principles are the same regardless of whether the membrane is rolled into a spiral element or cut into flat sections to fit into plate-and-frame units.

The plate-and-frame modules manufactured by Alfa Laval therefore use the same types of membranes as those offered for Alfa Laval spiral-wound elements. The unique concept with an open channel design makes the plate-and-frame module from Alfa Laval an obvious choice when the retentate has a high viscosity.

High permeate capacity

A plate-and-frame installation normally has a higher permeate capacity per unit of membrane area compared with what can be achieved using spiral-wound membrane elements. Industrial scale plate-and-frame modules have active membrane surface areas that range from 1.65 m² to 60 m². These can in turn be combined into larger systems using several modules placed either in series or parallel to achieve the required capacity.

Benefits

- open channel design for highly viscous products

- sanitary design for high product purity and cleaning

- same membrane types for both plate-and-frame modules and spiral-wound elements

- increased permeate capacity compared to spiral installations

- easy replacement of individual membranes

- flexible modular design for customized solutions

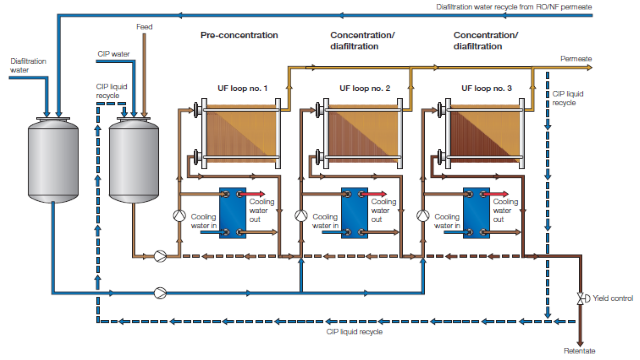

The above illustration shows an Alfa Laval plate-and-frame system incorporating diafiltration, which is often used to process high suspended solids and viscous feed solutions.

Typical applications include the recovery of antibiotics from whole broth, concentration of enzymes and dextrans as well as clarification of juice.

The plate-and-frame process illustrated can be also be combined with for example an Alfa Laval spiral process, which gives the advantage of using permeate from the spiral process as diafiltration water in the plate-and-frame process. This significantly reduces the need for process water.

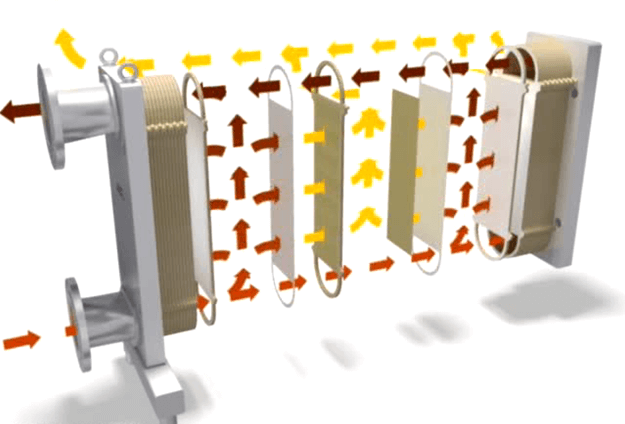

How it works

Flow pattern in a plate-and-frame module from Alfa Laval. Red is feed/retentate. Yellow is permeate.

The plate-and-frame module from Alfa Laval is designed with open channels across the membrane surface. The feed stream/retentate flows through these.

The membrane itself is supported by hollow plates with numerous slots that allow the permeate to collect and be removed from the module via the permeate collecting tubes.

Plate-and-frame modules use the membrane itself, aided by lock rings or strips, to seal off the feed/retentate from mixing into the permeate channels. This also prevents any leaks from the plate stack itself.

Due to the design of the plate-and-frame modules from Alfa Laval, individual membranes can be replaced without affecting the other membranes of the module.

Due to the design of the plate-and-frame modules from Alfa Laval, individual membranes can be replaced without affecting the other membranes of the module.

Customized solutions through flexible design

Alfa Laval membrane equipment is designed on a modular basis that gives a high degree of flexibility, as membranes are built into modules, modules are built into loops and loops are built into systems.

The design of a system can thus be customized to meet any process needs and it is easy to expand, if production requirements increases. This means that your investment can follow any required increase in production capacity, as and when you need it - and at a relatively low additional cost.