W-Sil

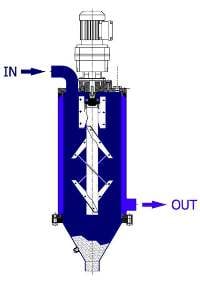

The W-SIL strainer is a self-cleaning brush strainer that is specially designed to remove coarse particles from process liquids, to protect downstream equipment such as centrifuges, heat exchangers, pumps, etc.

W-SIL self-cleaning brush strainers are ideal for filtering a wide range of process liquids. Any coarse particles or solids caught in the strainer are continuously removed from the filter surface, using brushes or scrapers. These particles are then collected in the sediment space, which is emptied at appropriate intervals.

The W-SIL strainer is ideal for filtering products that contain firm, non-fibrous particles. The unit is available with several different filter sizes and configurations, to suit particular applications.

The W-SIL strainer is available as a frame-mounted unit, complete with electrical cabinet and solids discharge valve.

Toiminto

The W-SIL strainer has a stainless steel casing surrounding a perforated strainer cylinder, through which the liquid passes. Any coarse particles suspended in the liquid are held back in the cylinder, and then forced downwards by rotating brushes mounted on a central shaft. This shaft is driven by an electrical gear motor mounted on top of the unit.

The collected particles are removed from the cone at the lower end. This cone is easy to open for inspection and access to the shaft and brushes.

Pipe connections for flushing the strainer are available on the bottom cone. Connections for instrumentation are located on the top of the unit.